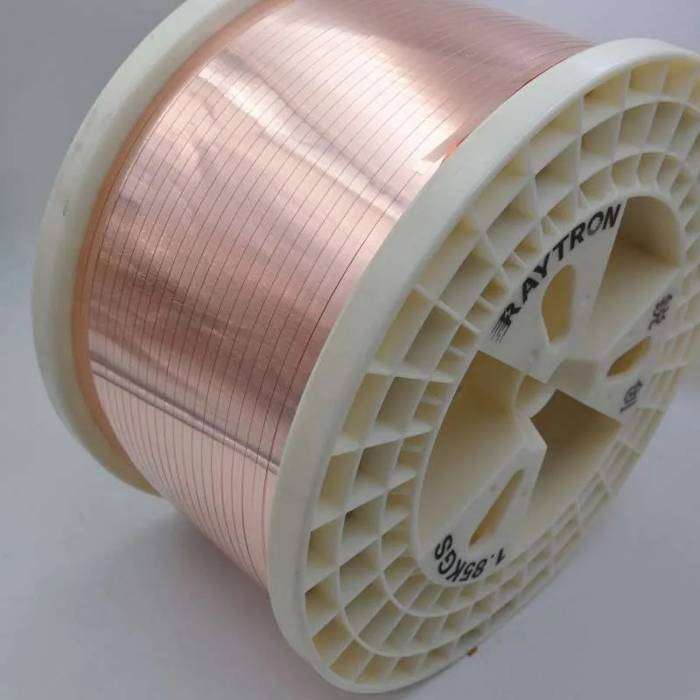

In new energy, batteries,Photovoltaic welding ribbonIn the fields of power generation, energy storage modules, etc., small-sized copper-clad aluminum flat wires have become the key conductor material, but truly "easy to use and stable" products are rare.

Have you ever encountered these problems?

?? Pain point 1: The product is unstable and there are big differences between batches?

Many small copper-clad aluminum factories on the market often encounter the following problems due to backward equipment and rough technology:

- The thickness of the copper layer varies, and the conductivity fluctuates greatly

- Large tolerance on flat wire width/thickness, inconsistent batch sizes

- Low production efficiency and repeated delivery delays

?? RaytronSolution:

Ruichuang adopts imported high-precision rolling mill + automatic thickness detection system, and controls the entire process from raw materials entering the factory to finished products leaving the warehouse through CNC to ensureDimensional consistency and electrical performance consistency from batch to batch. Let customers know what is going on with every purchase.

?? Pain point 2: Small specifications are difficult to process and dimensional tolerances cannot be controlled?

Small-sized (e.g. 0.05×3mm, 0.1×4mm, 0.15×2mm) copper-clad aluminum flat wires have extremely high requirements on equipment precision and composite technology. Many manufacturers are unable to guarantee that the copper layer will not be exposed, wrinkled or fall off.

?? Ruichuang solution:

Focusing on fine copper strip for more than ten years, Ruichuang has mastered the core technology of small-sized copper-clad aluminum composite - using multi-pass continuous rolling + annealing process,Maintain uniform copper layer, strong adhesion, smooth surface without defects in extremely narrow dimensions. Can be widely used inPhotovoltaic busbar,FPC Nickel Sheet, energy storage battery connection, BMS wiring and other precision scenarios.

?? Pain point three: Poor welding performance, easy to have cold solder joints or poor welding?

Low-quality copper-clad aluminum strips are not properly surface treated, which may cause the following problems during welding:

- Solder does not eat material

- The copper layer falls off or becomes black due to oxidation

- Insufficient welding strength affects product life

?? Ruichuang solution:

supportTin plating, and provide customized suggestions for different customer welding processes (laser welding/ultrasonic/reflow soldering, etc.) to ensure compatibility and welding efficiency. The measured welding yield is higher than 95%, and is widely used in automated welding production lines.

?? Pain point 4: Difficult customization, delayed delivery, and high minimum order amount?

Many corporate customers have reported:

"Our project requires a small amount of several thousand meters of special-specification flat wires, but the big factories are unwilling to take it, and the small factories can't do it."

?? Ruichuang solution:

Ruichuang has a flexible manufacturing production line.Support small batch proofing and customizationSpecial sizes such as 0.1×6mm, 0.15×3mm, 0.2×5mm, etc. can be quickly started up, and the delivery cycle is controllable. The minimum order is flexible and the delivery time is as fast as 3 days.

? Why choose Ruichuang? Five core advantages cannot be ignored:

- Quality Assurance: Industry-leading composite technology, strong copper layer adhesion, no peeling and no copper exposure

- Precision size: High dimensional control, thickness ±0.005mm, good width consistency

- Conductive stability: The electrical conductivity is 85~90%, comparable to the performance of pure copper welding strip

- Compatible with welding: Supports tinning, multiple welding methods are barrier-free

- Worry-free delivery: Sufficient stock of conventional specifications, fast response to customization, and guaranteed after-sales service

?? About Ruichuang

Ruichuang is a national high-tech enterprise and a national standard-setting unit. It has been focusing on the customization of small-sized copper strips and flat wires for more than ten years. Its products cover photovoltaic welding strips, FPC nickel sheets, CCS composite strips, copper-clad aluminum flat wires and other fields. Its customers are spread across new energy, battery modules, automotive electronics and other industries.