Photovoltaic welding ribbonThe production process has a vital impact on its final quality. The entire process from material selection to finished product delivery needs to be strictly controlled. To ensure the quality of photovoltaic welding ribbons, it is necessary to pay attention to the following key steps and control points:

1. Selection of raw materials

Selection of copper substrate: The main raw material of photovoltaic welding strip is copper strip. Copper material must have high conductivity and good ductility. The commonly used material is 99.99% high-purity oxygen-free copper, which can ensure that the welding strip has good conductivity and reduce power transmission loss.

Tin-plated material: The tin-plated layer is the key part of the solder strip, which plays a role in preventing oxidation and improving soldering performance. Generally, high-quality pure tin or tin alloy is used for plating. Whether to use lead-free or lead-free tin-plated materials needs to be selected according to customer needs.

2. Calendering and stretching

Copper strip rolling: The copper strip is rolled through a rolling mill to process its thickness to the required specifications. This process requires precise equipment and control systems to ensure that the copper strip has uniform thickness and a smooth surface.

Stretching treatment: The copper strip after calendering will undergo multiple stretching treatments to improve its strength and ductility. This process also requires strict tension control to prevent cracks or deformation of the copper strip during processing.

3. Cleaning and degreasing

Surface cleaning: Before entering the tinning process, the copper strip needs to be thoroughly cleaned and degreased to remove oil, oxides and other impurities on the surface of the copper strip to ensure that the tinning layer can be evenly attached to the surface of the copper strip.

Use acid or alkali washing: Acid or alkali washing is commonly used to deeply clean the copper strip, followed by high-temperature water washing and drying to ensure that there is no residual substance on the surface of the copper strip.

4. Tinning process

Hot dip tinning: After cleaning, the copper strip passes through a molten tin tank, and a layer of tin will be evenly attached to the surface. The thickness of the tinning needs to be precisely controlled according to different product requirements. The tinning temperature, time and purity of the tin liquid directly determine the quality of the solder strip and the welding effect.

Electroplating tin plating: Another commonly used method is electroplating, which uses electrochemical reaction to evenly plate tin on the surface of the copper strip. This method can better control the thickness of the coating and is suitable for some products with high thickness accuracy requirements.

5. Annealing

Soft and hard state control: During the production process, the solder strip needs to be annealed to achieve the desired soft or hard state. The annealing process eliminates the work hardening of the copper material through high-temperature heat treatment to ensure that the solder strip has good ductility and weldability. The annealing temperature and time need to be strictly controlled to ensure that the strength and softness of the solder strip meet customer requirements.

6. Rolling

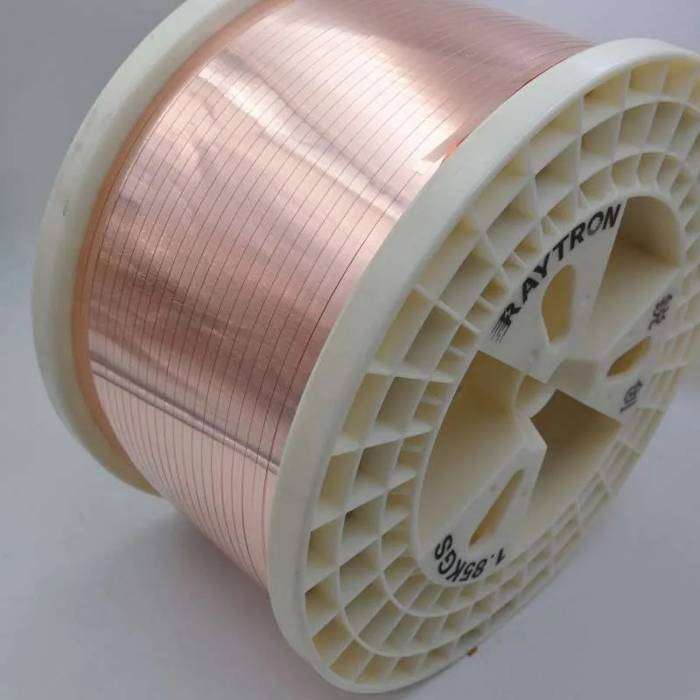

Rolling process: The rolled solder strip will be rolled into a specific diameter and wound and packaged by automated equipment. The tension must be controlled during the winding process to prevent the solder strip from bending or twisting during storage and transportation.

7. Quality Inspection

Thickness and size inspection: After production, the photovoltaic ribbon will undergo a series of size inspections to ensure that parameters such as thickness, width, and tin coating thickness meet product standards. Laser measuring instruments are usually used to detect these parameters.

Surface quality inspection: Use visual inspection or high-definition camera system to detect whether there are bubbles, scratches, oxidation spots and other quality issues on the surface of the solder strip.

Performance test: Test the key properties of the solder strip, such as conductivity, tensile strength, and ductility, to ensure that it meets thePhotovoltaic modulesRequirements for use.

8. Packaging and storage

Moisture-proof packaging: Qualified photovoltaic welding ribbons need to be strictly packaged in moisture-proof and dust-proof packaging, and vacuum packaging or moisture-proof bags should be used to avoid oxidation and corrosion during transportation and storage.

Labeling and tracking: The batch number, specifications and other information of the product will be attached during packaging to facilitate customers to track the production status of the product and ensure the traceability of the product.

9. Critical control points in the production process

Temperature and tension control: Temperature and tension are two very important parameters in the entire production process. Both the tinning process and the annealing process require precise temperature control. At the same time, tension control during stretching and coiling is also the key to ensure that the solder ribbon does not deform or wrinkle.

Tin plating thickness control: The thickness of the tin plating directly affects the firmness and conductivity of welding. Therefore, in production, it is necessary to detect the thickness of the tin layer in real time to ensure that the tin plating is uniform and of moderate thickness.

10. Environmental protection and production safety

Environmentally friendly production: During the production of photovoltaic ribbons, attention should be paid to the impact on the environment. The treatment of wastewater and waste gas must meet the standards, especially the treatment of pickling waste liquid and electroplating waste liquid, which need to be treated in special environmental protection facilities.

Safety in production: The tinning process involves high-temperature melting of tin, and operators need to be equipped with appropriate protective equipment. Production equipment must be regularly maintained to ensure stable operation of the equipment and avoid safety accidents.

By strictly controlling every production link and ensuring the accuracy of equipment and the standardization of operating procedures, the production of photovoltaic welding ribbons can achieve high quality standards and meet the high requirements of photovoltaic modules for conductivity, weldability and durability.