Workers who produce copper strips for terminals need to have certain professional skills and knowledge to ensure the smooth production process and product quality. The following are some key professional level and ability requirements:

1. Material knowledge

Metal Materials Science: Understand the properties of different copper materials and their alloys, and master the selection and application of materials to ensure the use of suitable raw materials.

Alloy knowledge: Be familiar with the characteristics of copper alloys (such as silver-plated copper, zinc-plated copper, etc.) and their applications in terminal production.

2. Production process

Rolling process: Master the operating principles of cold rolling and hot rolling, be able to operate the rolling mill skillfully, and adjust rolling parameters to meet product requirements.

Annealing process: Understand the temperature control and time setting of the annealing process, and be able to correctly implement the annealing operation to improve material properties.

Surface treatment: Master the coating process, understand the advantages and disadvantages of different coatings and application scenarios, and be able to perform related operations.

3. Equipment operation skills

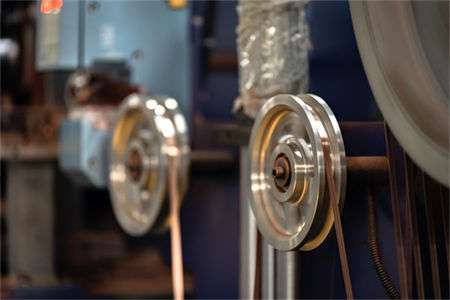

Mechanical operation ability: Proficient in operating various production equipment, such as rolling mills, annealing furnaces, coating equipment, etc., to ensure the normal operation of the equipment.

Equipment Maintenance: Have basic equipment maintenance and troubleshooting capabilities, and be able to detect and resolve equipment failures in a timely manner.

4. Quality Control

Testing technology: Be familiar with quality testing standards and methods, and be able to use various measuring tools (such as thickness gauge, hardness gauge, microscope, etc.) to test product quality.

Problem analysis ability: Have the ability to discover and analyze quality problems and be able to propose improvement measures.

5. Security Awareness

Safety operating procedures: Understand the potential safety hazards in the production process, be familiar with safety operating procedures, and ensure the safety of yourself and others.

Emergency response capability: Have the ability to handle sudden safety incidents and take effective response measures in emergency situations.

6. Teamwork and communication skills

Teamwork: Ability to work effectively with other workers, engineers, and managers to promote production efficiency.

Communication skills: Ability to clearly express problems and needs in the production process and maintain good communication and coordination.

7. Continuous learning ability

Technology update: Have the ability to learn new technologies and processes, pay attention to industry trends and technological progress, and continuously improve one's own professional level.

8. Computer application skills

Data recording and analysis: Master basic computer operation skills and be able to use relevant software to record production data and perform simple data analysis and statistics.

Summarize:

Workers who produce copper strips for terminals need to have solid professional knowledge and practical skills to complete their work efficiently and safely in complex production environments such as high temperature, high pressure and chemical treatment. This not only affects the quality of the product, but also directly affects production efficiency and the overall competitiveness of the enterprise.