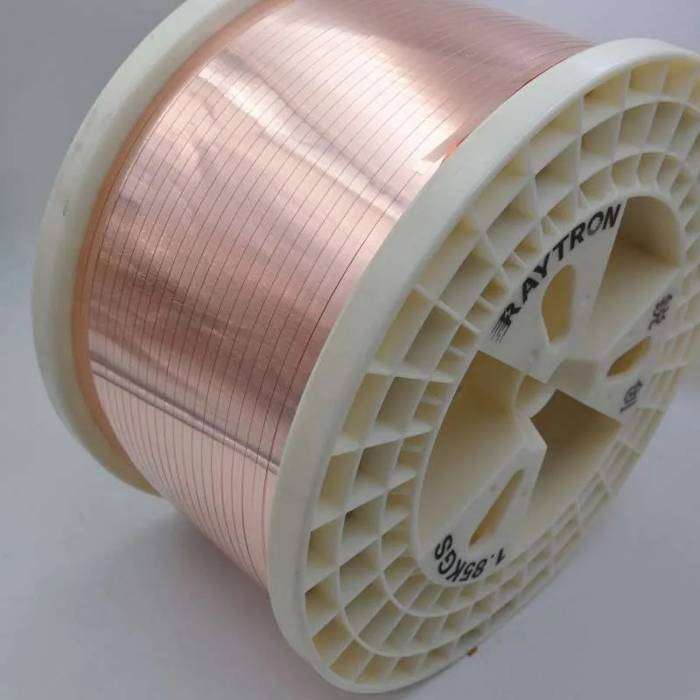

Copper clad aluminum stripThe application, advantages and potential risks of (CCA) in photovoltaic systems are summarized, and the benefits of copper-clad aluminum strip and application scenarios are introduced.

Advantages of Copper Clad Aluminum (CCA)

Cost Advantage

The biggest advantage of copper-clad aluminum strip is its low cost. Aluminum as the inner core material significantly reduces production costs, while copper as the outer layer material provides sufficient conductivity, making it very suitable for cost-sensitive low-power or short-term use photovoltaic systems.

Light weight

Copper-clad aluminum strip is much lighter than pure copper welding strip, which reduces the total weight of the photovoltaic system and facilitates transportation and installation.

Suitable for low power applications

In photovoltaic systems with low power requirements, copper-clad aluminum strips can meet basic power transmission requirements and provide a certain degree of conductivity.

Hidden dangers and potential risks of copper clad aluminum (CCA)

Conductivity gap

Although the copper layer of copper-clad aluminum strip can provide certain conductivity, it still has a higher resistance than pure copper welding strip. Especially at high power output, the voltage drop of copper-clad aluminum strip increases, resulting in a decrease in power transmission efficiency and affecting the overall power generation capacity of the system. During long-term operation, the conductivity of copper-clad aluminum strip may further decrease, especially under high load conditions.

Low mechanical strength

The tensile strength and bending resistance of copper-clad aluminum are lower than those of pure copper, which means that copper-clad aluminum strips may break or deform under long-term exposure to severe weather conditions, affecting the stability and reliability of the photovoltaic system. Long-term temperature changes, wind, temperature and humidity may exacerbate the damage of copper-clad aluminum.

Difference in thermal expansion coefficient

The difference in thermal expansion coefficients between copper and aluminum will generate stress during temperature changes, which may cause delamination or deformation of the copper-clad aluminum strip, affecting the stability of the welding contact and further reducingPhotovoltaic modulesoverall efficiency.

Corrosion issues

Copper-clad aluminum strips are prone to electrochemical corrosion in humid or corrosive environments, especially in areas containing electrolytes. The copper layer may oxidize or corrode, which increases contact resistance, reduces conductivity, and may cause the solder strip to become brittle or break, greatly affecting the long-term operation and reliability of photovoltaic modules.

Processing technology issues

During the processing of copper-clad aluminum strips, insufficient copper layer thickness or incomplete bonding may lead to a decrease in the strength and conductivity of the soldering strip, which is prone to failure, especially in extreme environments.

Environmental adaptability issues

The hidden dangers of copper-clad aluminum strips will be magnified when used in humid environments, areas with large temperature differences between day and night, especially in high humidity, low temperature or extreme climate conditions. Moisture erosion and oxidation will aggravate the bond damage between the copper layer and the aluminum substrate, resulting in poor electrical contact, thus affecting the reliability of the system.

International standards and recommendations

IEC Standards

According to the standards of the International Electrotechnical Commission (IEC), although copper-clad aluminum materials have advantages in cost control, their performance is poor in extreme environments such as high load, high temperature and high humidity, which can easily lead to a decrease in conductivity. IEC recommends that pure copper materials be given priority in application scenarios that require long-term stable operation, especially in the long-term operation of photovoltaic systems, where the conductivity and reliability of pure copper are more stable.

ASTM Standards

According to the standards of the American Society for Testing and Materials (ASTM), ASTM B609 points out that copper-clad aluminum materials may cause a decrease in conductivity in high temperature and humid environments, affecting the operation of electrical systems. The ASTM B170 standard emphasizes the advantages of pure copper in conductivity, durability and safety, and is particularly suitable for photovoltaic systems that require high long-term stability.

Photovoltaic application standards

In the photovoltaic field, the IEC 61730 standard recommends the use of pure copper welding strips instead of copper-clad aluminum strips, especially in applications with high reliability requirements. Pure copper materials can provide more stable and lasting performance, ensuring long-term stable operation of photovoltaic systems.

Summarize

Although copper-clad aluminum strips have lower costs and certain application advantages, the hidden dangers in high power output, long-term stability, environmental adaptability, etc. cannot be ignored. When used in high temperature, high humidity, humid or harsh environments, copper-clad aluminum strips may have problems such as reduced conductivity, insufficient mechanical strength, and increased corrosion, which may lead to reduced efficiency and increased failures of photovoltaic systems in long-term operation.

According to the recommendations of international standards, although copper-clad aluminum strips are suitable for low-power, short-term photovoltaic applications, pure copper welding strips are still a more reliable choice for photovoltaic systems that require long-term stability. When selecting welding strip materials, cost, performance, use environment and long-term stability of the system must be comprehensively considered.