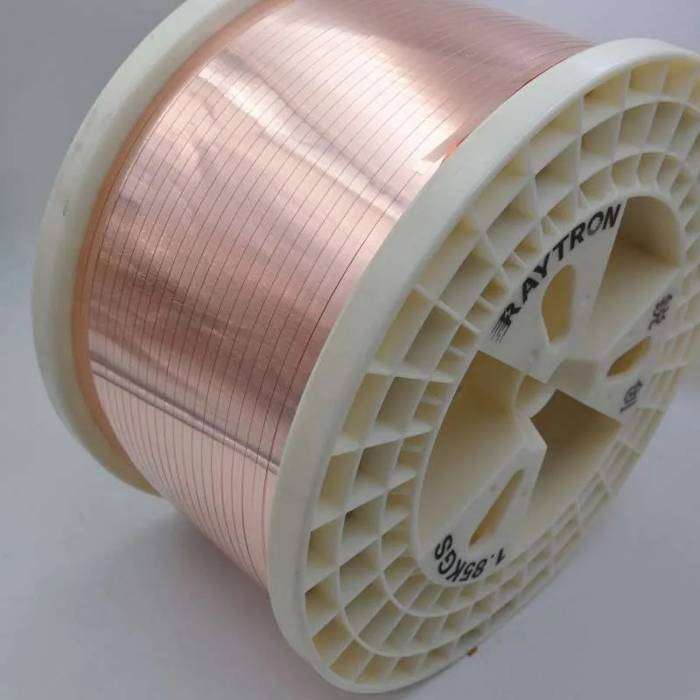

PhotovoltaicplatingtinCopper StripWhat is the material

I. Functionality

Photovoltaic ribbons play a role of connection and convergence in the production process of components. The current of the battery is obtained through the welding process. The ribbon electrodes are then effectively connected to the junction box in series or parallel. Therefore, photovoltaic welding rods are further divided into two types: photovoltaic interconnection ribbons andPhotovoltaic busbar.

PV tabbing wire is welded on the front and back of the cell, which will lead to the current collected by the cell. At the same time, the thickness should not be too thick so as not to cause the cell to collapse during the lamination stage.

During the module replication process, the cells are connected in series in a certain number. The selection of the photovoltaic busbar is to minimize power loss. This requires it to have a certain width to reduce its own resistance.

II. Composition

Composition of photovoltaic strips

Photovoltaic welding ribbonGenerally, it consists of two parts: copper-based material and surface coating. Photovoltaic carbon ribbons are mainly distinguished by the composition of the surface coating.

2.1 Copper-based materials

During the use of photovoltaic carbon ribbon, copper plays the main role of conductivity. The higher the purity of copper, the lower the resistivity, the stronger the load-bearing capacity and the better the plasticity. The copper-based material of photovoltaic carbon ribbon is generally high-purity oxygen-free copper. Oxygen-free copper refers to pure copper that does not contain oxygen or any deoxidation.

Oxygen-free copper is pure copper that does not contain oxygen or any deoxidizer residue. However, it actually contains a very small amount of oxygen and some impurities. According to the standard, the oxygen content does not exceed 0.03%, the total content of impurities does not exceed 0.05%, and the purity of copper exceeds 99.95%.

According to the oxygen content and impurity content, oxygen-free copper is divided into No. 1 and No. 2 oxygen-free copper. The purity of No. 1 oxygen-free copper reaches 99.97%, the oxygen content does not exceed 0.003%, and the total impurity content does not exceed 0.03%. The purity of No. 2 oxygen-free copper reaches 99.95%, the oxygen content does not exceed 0.003%, and the total impurity content does not exceed 0.05%.

The copper of the photovoltaic belt is No. 2 oxygen-free copper with a purity greater than 99.99%.

2.2 Coating

Although the main conductive role is played by the copper substrate, the importance of the surface coating of the photovoltaic ribbon cannot be ignored. The difference between photovoltaic ribbons lies in the composition of the coating and its content.

Coating compositions generally include the following types:

Tin-lead: 60/40; 63/37 (183°C).

SnPbAg: 62/36/2 (178°C)

Tin-silver: 96.5/3.5 (221°C)

SnAgCu:96.5/3.0/0.5 (217-220℃)

Sn100: pure tin (232°C).

Among them, the role of silver (Ag) is to improve the mechanical strength of the photovoltaic strip and improve the thermal fatigue strength in the case of lead-free. Compared with lead, silver has poor ductility, poor processability and high cost. The role of copper (Cu) is to improve the wettability of the solder and improve the thermal fatigue strength. This copper is not the copper used for copper-based materials.

The most commonly used coating composition is tin-lead coating. There are 63, 37 coatings and 60, 40 coatings. First, the cost is low, and second, it is easy to use and has a good effect. However, since lead has a certain toxicity, it should be protected when used.

III. Important parameters

◆Copper base: oxygen-free copper/T2 copper, copper content ≥99.99%, conductivity ≥98

◆Copper-based resistivity: oxygen-free copper ≤ 0.0165Ωm㎡/m T2 copper ≤ 0.0172Ωm㎡/m

◆Coating composition: 63%Sn37%Pb

◆Coating thickness: single-sided coating 0.01~0.05mm, uniform coating, smooth surface.

◆Coating melting point: 183℃.

Tensile strength: soft state ≥25kgf/㎡, semi-soft state ≥30kgf/㎡.

◆Solder strip elongation rate: soft state ≥30% semi-soft state ≥25%.

◆Width error: ±0.1mm

Thickness error: interconnecting strip ±0.01mm, converging strip ±0.015mm.