aboutSolar PhotovoltaicThere are two types of soldering of solder strips, one is the soldering of leaded solder strips, and the other is the soldering of lead-free solder strips. Among them, lead-free solder strips are easier to solder. Generally speaking, as long as the appropriate flux is selected, the temperature compensation of the soldering iron is sufficient for use. But the soldering of lead-free solder strips is indeed very troublesome, and many manufacturers find it a headache. First of all, you need to choose a suitable soldering iron for lead-free soldering. For manufacturers, choosing a lead-free soldering station with adjustable power is a good choice. Lead-free soldering stations generally use DC power supply with adjustable voltage. The advantage of DC soldering irons is fast temperature compensation. This is incomparable to AC temperature-controlled soldering irons. For lead-free soldering, a 70-100w soldering iron should be selected according to the thickness and area of the battery. Soldering irons less than 70w generally have problems in lead-free soldering.

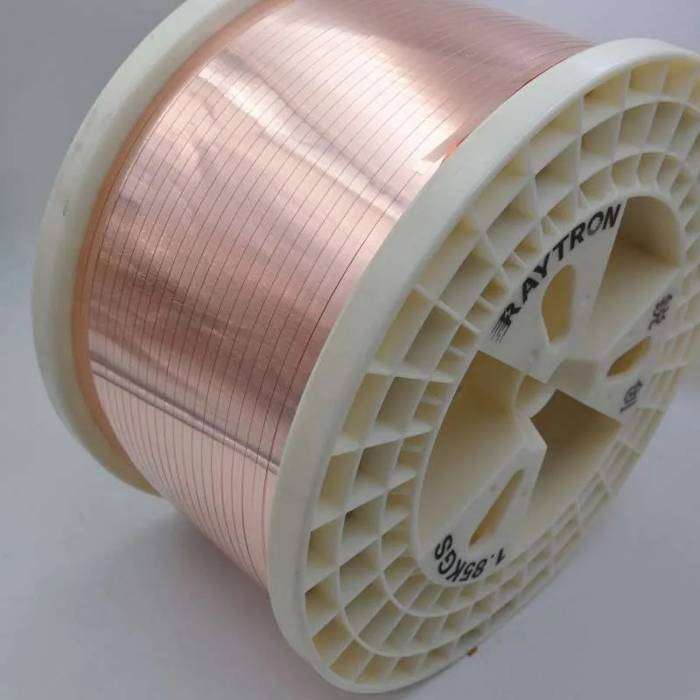

Lead-free soldering ribbon

In the process of soldering lead-free solder strips, manufacturers should pay attention to adjusting the workers' soldering habits. The fluidity of lead-free solder is not strong. And the soldering speed should be slower. When soldering, you must wait until the solder is completely dissolved before moving the soldering iron, and the speed of moving the soldering iron should be slow. If you find that the solder solidifies during the process of moving the soldering iron, it means that the temperature of the soldering iron tip is low, and you need to adjust the temperature of the soldering iron tip. The soldering iron tip moves steadily until the solder flows smoothly.

Correct use of lead-free solder ribbon

With the implementation of the EU ROHS directive in June 2006, my country's photovoltaic industry exports are facing the choice of lead-free. Compared with traditional photovoltaic soldering ribbons, lead-free soldering ribbons have many disadvantages. How to overcome these disadvantages is a process problem that many photovoltaic manufacturers urgently need to solve.

Lead-free solder strips are divided into many types according to the composition of the coated solder. The most widely used lead-free solder is 305 solder, which contains 3% of silver and 0.5% of copper. The advantages of this solder are good solderability, high solder, and a melting point of 218C. The soldering temperature required for the soldering of battery cells is very high, and it is difficult for ordinary internal heating soldering irons to meet the temperature requirements. Therefore, a high-power soldering iron should be used for the soldering of lead-free solder strips. It is generally recommended to use 30-40W higher than that for soldering lead-containing solder. For example, a 35W soldering iron was originally used. Then a soldering iron of more than 70W must be used for lead-free soldering.

Flowability of lead-free solder

Lead-free solder has poor fluidity. When soldering, wait until the tin coated with solder is fully melted before moving the soldering iron, and move the soldering iron slowly. The soldering iron tip receives the melted solder and moves slowly. If the solder is found to be solidified or not completely melted, it means that the temperature compensation of the soldering iron tip is not enough. In addition, the temperature of the soldering iron tip is already lower than the melting point of the solder.

Many lead-free temperature-controlled soldering irons on the market are most likely to have this phenomenon. When the soldering iron tip touches the battery, the temperature reaches 400°C. The temperature of the soldering iron tip will suddenly drop below 250°C, making it difficult to continue soldering. It is recommended that manufacturers choose a lead-free soldering station, adjust the temperature of the soldering iron by adjusting the DC voltage, and choose a lead-free soldering station with a large iron head. Do not choose a thermomagnetic controlled temperature-controlled soldering iron. The requirements for soldering irons for welding different types of battery cells are different. Generally, large battery cells have higher requirements for the thickness of the soldering iron. And large battery cells have higher requirements for the area of the soldering iron. Choosing a DC lead-free soldering station can basically solve the problem of welding temperature.

Lead-free solder strips will change color soon after soldering. This is because lead-free solder is more easily oxidized, which is a normal phenomenon.