Battery TabIt is an important part of lithium-ion batteries. The battery is divided into positive and negative electrodes. The tabs are metal conductors that lead out from the positive and negative electrodes of the battery cell. In short, the positive and negative tabs of the battery are the contact points during charging and discharging. Generally speaking, the positive and negative electrodes of lithium-ion batteries are made of aluminum alloy, while the negative electrode is made of nickel. The negative electrode can also be made of nickel-plated copper.

Nickel materials are mainly used in small digital batteries, such as: mobile phone batteries, mobile power batteries, tablet batteries, smart transmission equipment batteries, etc. Battery tabs plated with copper-nickel materials are mainly used for: Mainly used in power batteries and high-rate batteries.

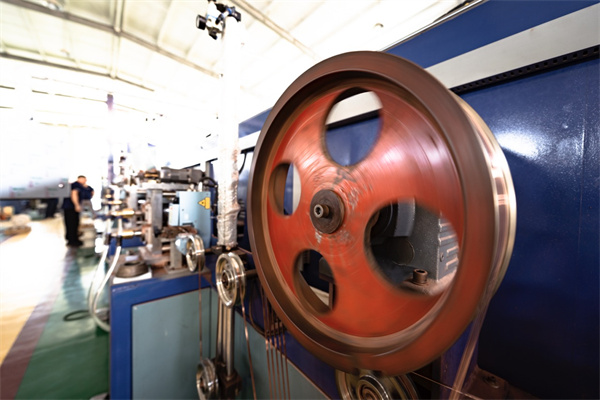

RaytronThe tabs of lithium-ion batteries produced by new energy generally use disc tabs (the entire metal strip is rolled into a disc after being coated by the equipment), which is used in automated production lines. This packaging method is also called carrier tape packaging. There is also a plate tab (the metal strip is cut into independent sheets after being coated, and then arranged in a row with two thin transparent plastic sheets in between), which is used in general production lines. These two packaging methods are mainly used.

Lithium-ion battery tabs also require surface treatment. Currently, the commonly used surface treatments for workpieces are electroplating nickel and chemical nickel plating. The thickness of the electroplating nickel layer is 1.8±0.3um, and the thickness of the chemical nickel plating layer is 1.0±0.3um. In addition, the copper-nickel-plated solder tabs must ensure conductivity; the nickel after surface treatment plays a role in preventing copper oxidation. If the solderability of the copper-nickel-plated solder tabs is to be guaranteed, the surface passivation film of the solder tabs needs to be treated again.