Photovoltaic welding ribbonIt is an important part of the battery assembly, and the welding technology of photovoltaic welding ribbon is even moreSolar CellsA vital part of manufacturing. What are the photovoltaic ribbon welding techniques? The following are general welding techniques for photovoltaic ribbons:

1. Arc Welding:

Conventional Arc Welding: This is a traditional welding method, usually using copper or aluminum photovoltaic ribbon. When welding, an arc is formed between the electrode and the workpiece, melting the welding material to connect the cells. This method requires a stable power supply and welding skills.

Laser Welding: Laser welding is a high-precision, non-contact welding method. A laser beam is used to melt photovoltaic ribbons and cells to create a strong and durable connection. This method is often used in the manufacture of high-efficiency solar cells because it allows for more precise welding.

2. Resistance Welding:

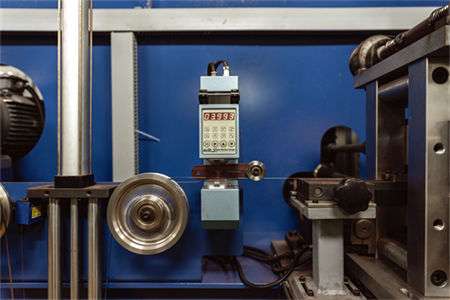

Spot Welding: Spot welding is a method of joining PV ribbons and cells using electric current and pressure. Electric current flows through the solder joints, causing them to heat and melt, and then pressure is used to connect the joints together. This is a fast and reliable welding method suitable for high-volume manufacturing processes.

3. Ultrasonic Welding: Ultrasonic welding uses high-frequency ultrasonic vibrations to connect photovoltaic ribbons to cells. This method is suitable for thin solar cells because it does not generate excessive heat at the welding point.

4. Pressure Welding: Pressure welding uses mechanical pressure to connect the photovoltaic ribbon to the cell. This method usually requires preheating the welding point to improve the welding quality.

5. Hot Press Welding: This is a welding method that combines heat and pressure and is commonly used to connect photovoltaic ribbons in high-efficiency solar cells. Hot press welding uses preheat and pressure to melt the welding material and form a strong connection after cooling.

When choosing the right welding technology, you need to consider the type of solar cell, material, and design requirements. Different technologies may be suitable for different types of solar cell manufacturing. In addition, the quality of the welds needs to be ensured during the welding process to ensure that the current can effectively flow through the connection points, thereby ensuring the performance and reliability of the solar cell. The welding operation needs to be performed by trained professionals to ensure the accuracy and quality of the weld.